Sanitary Welding: 6 Mistakes That Cost You

Sanitary welding involves protecting product purity, complying with industry regulations, and minimizing contamination risks. In the food processing and pharmaceutical industries, even minor oversights can lead to shutdowns, recalls, or compliance violations.

These issues happen in Muncie and beyond. If you’re relying on outdated techniques or cutting corners, you’re likely making some of the six sanitary welding mistakes that cost you.

1. Skipping Joint Prep

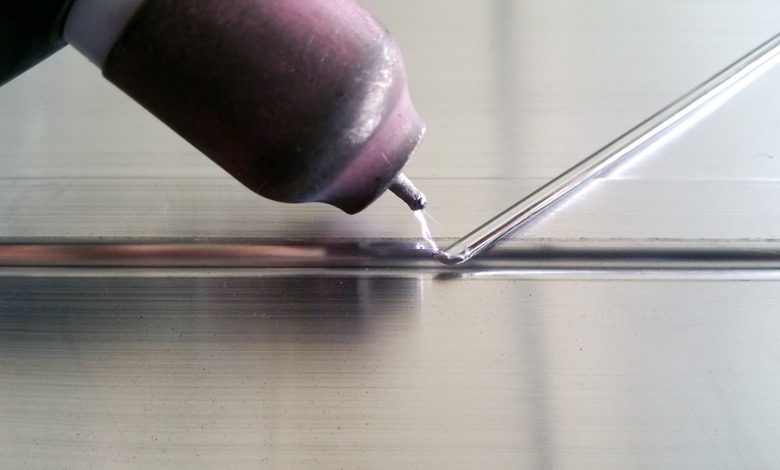

Every weld starts with the joint, and problems multiply fast when that surface isn’t prepared. Dirty, misaligned, or uneven joints create hidden pockets where bacteria thrive, or cause incomplete fusion that fails under pressure.

Joint prep includes cleaning, alignment, and matching surface finishes. Refer to equipment manuals, ASME BPE guidelines, or manufacturer recommendations to ensure your process meets sanitary requirements.

2. Not Removing Burrs and Sharps

Even if a weld looks clean from the outside, it may contain dangerous internal features—burrs, spatter, and sharp edges that interfere with flow and trap debris. These small imperfections can lead to bacterial growth or damage to products as they pass through the system.

To meet sanitary standards, welds must be free of surface roughness. Mechanical or electrochemical polishing may be necessary to achieve a smooth, drainable finish.

3. Overlooking Defect Detection

Defects like pinholes, cracks, or lack of fusion are seldom visible to the naked eye, especially in orbital welds. Relying on visual inspection alone can leave critical flaws undiscovered until a failure occurs or, worse, until a product recall happens.

Many facilities use advanced defect detection in orbital welding to confirm precision and repeatability. Integrating this technology reduces risks and supports compliance in various environments, from clean rooms to dairy processing lines.

4. Overstressing Welded Surfaces

Thin-walled sanitary tubing is sensitive to overhandling. Clamping too tightly, misaligning joints, or applying excess pressure during setup can stress the metal and create weak points that lead to leaks or cracking. Preventing this requires careful fixture design and a controlled welding environment. It’s not just about how you weld, but how you prepare everything leading up to it.

5. Using Bolts for Structural Support

Threaded bolts and rods are easy to install, but they’re magnets for contamination. Their threads and crevices are nearly impossible to clean, particularly in wet or enclosed areas. Whenever possible, use welded supports or fully enclosed mounting systems in place of these. Prioritizing fast assembly over long-term cleanliness is one of the most common and costly design missteps.

6. Neglecting Specialized Labor

Many welders know how to join metal. Fewer know how to do it cleanly, consistently, and to sanitary standards. Wherever you work, don’t underestimate the value of specialized skills! Hiring generalists or skipping training may be the worst sanitary welding mistakes that cost you.