Things To Consider When Choosing a Screw Ball Assembly

Ball screw assemblies are indispensable in automated and mechanical systems. They enable precise, efficient linear motion across a wide range of industries, including manufacturing, robotics, aerospace, automotive, and medical technology. Selecting an assembly carelessly could lead to premature failure, increased costs, or compromised performance. These considerations when choosing a screw ball assembly will help you select options that suit your application.

Load Capacity Requirements

Ball screw assemblies must accommodate specific load capacity requirements for optimal performance and long-term durability. The load capacity includes both static and dynamic loads. Static load capacity refers to the maximum force the assembly can withstand when stationary without permanent deformation. Dynamic load capacity is the repetitive and fluctuating forces exerted during operation, such as in high-speed or continuous motion scenarios.

Speed and Accuracy

Speed and accuracy are central to ball screw performance, especially for productivity and precision. The lead of the ball screw determines the distance the nut moves per shaft revolution. Higher leads allow faster motion but may sacrifice accuracy, and lower leads offer exceptional precision at the expense of speed. Evaluate your speed and accuracy needs carefully to find the right balance for your application.

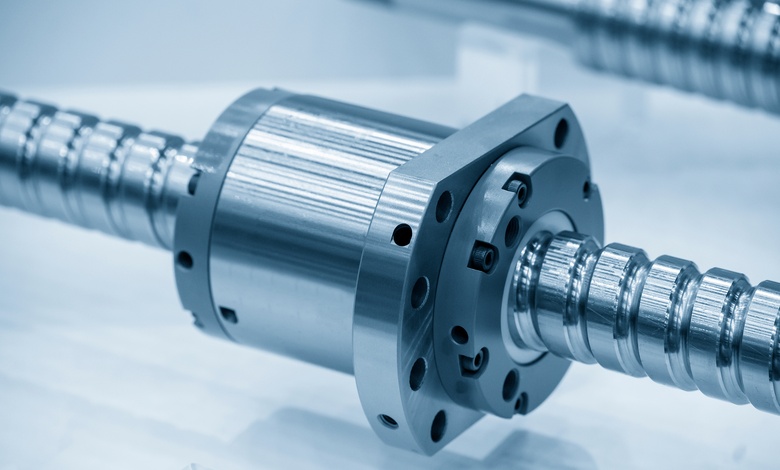

Design and Material Selection

The design and material of the ball screw assembly determine its durability and environmental compatibility. Standard options include ground or rolled ball screws. Ground ball screws provide superior precision and are ideal for high-accuracy applications. Rolled ball screws are cost-effective and suitable for moderate-precision applications. Stainless steel adds corrosion resistance to systems operating in humid or chemically harsh environments.

Operating Environment

The environment in which the ball screw assembly operates affects its performance and lifespan. Temperature, humidity, and potential exposure to contaminants should guide your selection. You can learn about temperature effects on ball screw assembly performance to prevent reduced efficiency or mechanical failure. Protective measures, like applying seals or specialized lubricants, keep the assembly functional.

Maintenance and Longevity

Understanding the maintenance requirements and expected lifespan of a ball screw assembly is essential for reliable operation. Performing maintenance, such as lubrication and alignment checks, reduces wear and tear and ensures the mechanism performs consistently over time. A high upfront investment in a durable ball screw assembly results in lower maintenance costs and an extended operational life.

Choosing a ball screw assembly involves understanding your needs. You can select an efficient and long-lasting assembly by considering load capacity, speed, accuracy, design materials, operating environments, and maintenance requirements.