Trainings and Certifications Needed for Cold Saw Use

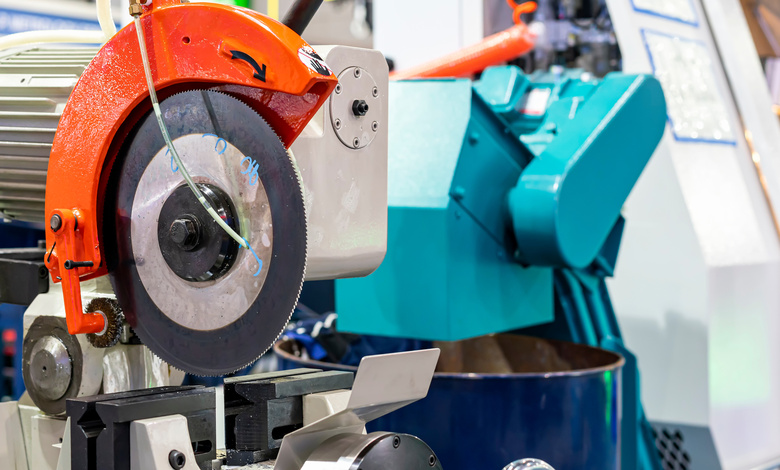

Cold saws are vital tools in metalworking, providing precision in cutting various metals efficiently. However, operating a cold saw requires more than just familiarity with its functions.

Proper training and certifications ensure safer operation and enhance productivity and precision in industrial settings. If you’re a young professional, or a trade school student, or already working with cold saws, here’s a look at the training and certifications needed for cold saw use.

The Importance of Safety Training

The operation of cold saws carries inherent risks, such as exposure to sharp blades and high-speed machinery. Before using one, you need comprehensive safety training to mitigate risks. Key aspects include proper handling techniques, operational limits, and maintaining a clean, organized workspace around the machine.

Specific safety considerations for using a cold saw machine include wearing personal protective equipment, such as safety goggles and gloves, to protect against flying debris, and ensuring that blades are secure and maintained properly. Training often incorporates these best practices to reduce accidents and equipment failure.

Enroll in Formal Training Programs

Vocational schools and training centers offer courses specifically tailored to metalworking machinery, including cold saws. These programs combine theoretical knowledge with hands-on practice, helping you gain the technical expertise needed to operate cold saws proficiently and safely.

Manufacturers and distributors may also provide customized training sessions. This type of formal education bridges the gap between understanding the mechanics of the machine and applying that knowledge in real-world scenarios.

Gain Proficiency through On-the-Job Training

Nothing accelerates mastery like real-world experience. On-the-job training allows you to apply classroom theories in a practical setting. Under the guidance of seasoned professionals, you will build confidence in handling cold saws while learning tips and tricks that only hands-on work can provide.

Mentorship plays a critical role here. Experienced coworkers or supervisors can troubleshoot unexpected challenges, such as blade wear or performance inconsistencies, which aren’t always covered in formal training. Regular feedback ensures continuous improvement and makes you more effective at your job.

Obtain Manufacturer Certifications

Many cold saw manufacturers offer certifications tailored to their specific models. These certifications are a valuable asset and demonstrate your ability to operate their equipment safely and efficiently. They often involve short training sessions and exams that test your understanding of the machine’s features and operational guidelines.

Stay Updated With Continued Education

Cold saw technologies and safety standards evolve over time. Regularly updating your skills through continued education is a must to stay competitive and safe.

Workshops on advanced cutting techniques, blade material science, or updates in OSHA safety protocols are excellent ways to enhance your knowledge. Additionally, attending industry events or subscribing to trade journals can keep you informed on the latest advancements and practices in the field.

Operating a cold saw requires a range of trainings and certifications. Enroll in formal courses provided by vocational schools or manufacturers and enhance your real-world expertise through on-the-job learning.