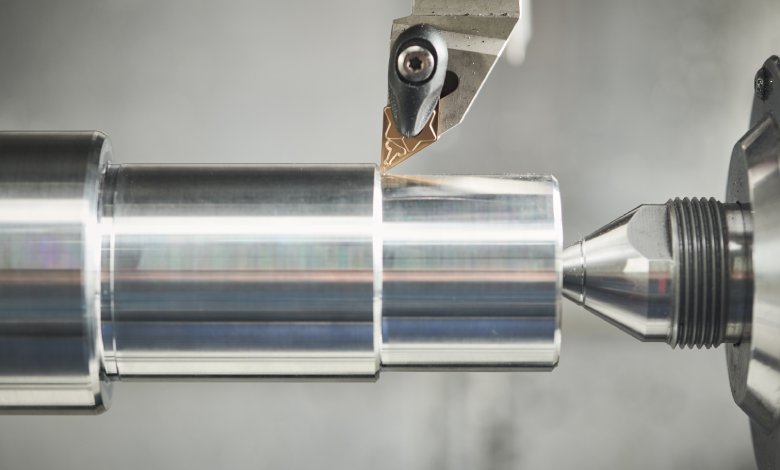

Top 4 Industries Benefiting From CNC Machines

Computer numerical control machines (also known as CNC machines), are reshaping the way we think about manufacturing. Their ability to reduce production times while creating precise and customized parts makes them invaluable in the manufacturing field. But which industries reap the biggest rewards from this tech, and what other ones can benefit? Let’s take a closer look at the top four industries benefiting from CNC machines.

Aerospace

The aerospace industry has long demanded precision, detail, and strength from its components. CNC machines are the perfect tools for that industry’s many high-flying projects and purposes. Turbine blades, engine components, airframes, and other assemblies have complex designs and extremely, almost unforgivably tight tolerances. CNC machines ensure accuracy and reliability for these critical components, where the slightest flaw may have deadly consequences. CNC machines deliver precision, accuracy, and reliability.

Automotive

Coming back down to Earth, CNC machines are game changers in the automotive industry. They’re frequently employed to produce high-quality vehicle parts and mechanisms, like gearboxes, engine blocks, crankshafts, and other equipment. Automakers rely on CNC technology because it can mass produce these parts while maintaining their exact specifications. CNC machines are also a boon to prototyping, allowing manufacturers to build, test, and refine designs before full production.

Medical

Sometimes the most important “machine” CNC devices can help rebuild is the human body. CNC machines are called on to manufacture medical devices, surgical instruments, and implants. Prosthetics and orthopedic aids are designed to meet medical-grade standards. Customization permits personalized solutions for individual patients as well.

Prototyping and Custom Manufacturing

CNC machines aren’t just used to make parts for complex vehicles like airplanes and automobiles. Smaller companies and startups employ CNC machines to develop prototypes for new products, one-off designs for presentations, and even custom parts that require accuracy and precision but don’t need to be mass produced. In short, they’re dream-making machines for little companies that are just getting started!

While those are the top four industries benefiting from CNC machines, there’s room for more. Despite some of the myths you may have heard about CNC machines, they’re transforming companies everywhere by making processes faster, more precise, and cost-effective. If you want to improve efficiency in manufacturing, CNC technology is the way to go.

Investing in CNC technology is not just about improving performance—it’s about staying competitive in an evolving market. Whether you’re in aerospace, healthcare, or another field, CNC machines are key to precision and innovation. Could CNC machines provide the competitive edge your business needs?