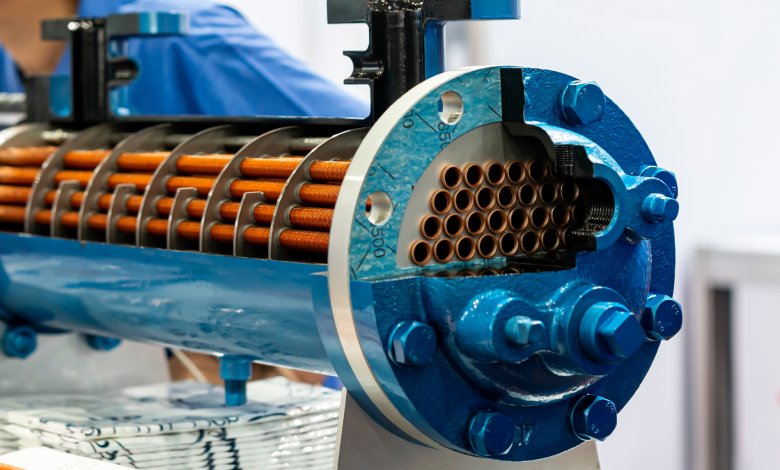

How Copper-Nickel Alloys Enhance Heat Exchanger Efficiency

Heat exchangers often struggle with corrosion, fouling, and thermal inefficiency. Traditional materials like steel and aluminum can fail under harsh conditions, leading to frequent maintenance and downtime.

Copper-nickel alloys offer a superior solution that enhances heat exchanger efficiency. These specialized alloys combine copper’s excellent thermal conductivity with nickel’s corrosion resistance to create materials that thrive in demanding environments.

Superior Corrosion Resistance

Copper-nickel alloys excel in environments where other materials quickly deteriorate. Seawater applications are a prime example of how their natural resistance to chloride-induced corrosion is beneficial. The nickel content forms a protective oxide layer that prevents pitting and crevice corrosion and extends equipment lifespan.

Power plants using seawater cooling systems report operational periods of 20 to 30 years with copper-nickel heat exchangers, compared to 5 to 10 years with standard steel units. This extended lifespan reduces replacement costs and minimizes operational disruptions.

Enhanced Thermal Conductivity

Copper-nickel alloys enhance heat exchanger efficiency because of their thermal properties. Pure copper conducts heat exceptionally well, and adding nickel improves conductivity while adding strength and corrosion resistance.

A comparison between 90/10 and 70/30 copper nickel alloy reveals their different thermal characteristics. The 90/10 alloy (90 percent copper and 10 percent nickel) has higher thermal conductivity, which is ideal for applications prioritizing heat transfer. The 70/30 alloy trades some conductivity for increased strength and corrosion resistance, suiting more aggressive environments.

Reduced Biofouling Properties

Marine organisms struggle to attach to copper-nickel surfaces due to their natural biocidal properties. This self-cleaning characteristic supports heat transfer efficiency, unlike steel surfaces that accumulate biological growth.

Offshore platforms using copper-nickel heat exchangers report 40 to 60 percent less fouling compared to alternative materials. Reduced fouling means consistent thermal performance and lower cleaning maintenance requirements.

Cost-Effective Long-Term Operation

While copper-nickel alloys cost more initially, their durability delivers considerable savings in the long run. Reduced maintenance schedules, extended replacement intervals, and consistent performance create a favorable total cost of ownership.

These alloys also provide more operational reliability than most materials. Chemical processing plants report 75 percent fewer unplanned shutdowns when switching from carbon steel to copper-nickel heat exchangers.

Various industries trust copper-nickel alloys for their unique characteristics. Selecting the right copper-nickel composition depends on specific operating conditions and intended use. The investment in copper-nickel technology pays dividends through extended equipment life, reduced downtime, and consistent thermal performance.