Different Process Options To Manufacture Products

In the ever-evolving world of manufacturing, understanding the multitude of process options available to manufacture products can be a game-changer. From traditional methods to cutting-edge technologies, each process has its unique benefits and drawbacks. This blog aims to demystify these processes, providing you with a comprehensive guide to make informed decisions about your production strategies. Whether you’re a seasoned manufacturer or a newcomer in the industry, understanding the different process options to manufacture products will serve you well in your future.

Part Molding

Part molding processes are commonly used in the production of complex shapes that would be otherwise challenging to create with other techniques. There are several variations of these processes, so you need to carefully consider various part-molding factors before settling on a process. In general, however, these processes involve pouring a liquid material, such as plastic or metal, into a mold. Once the material hardens, the mold is removed, revealing a finished part. This method is ideal for mass production due to its capability to continuously produce identical parts. Examples of part molding processes include injection molding, blow molding, and rotational molding.

Batch Process Manufacturing

Batch process manufacturing involves producing a set quantity of a product in a series of steps. After each batch is completed, the equipment is cleaned and prepared for the next batch. This method offers flexibility by allowing manufacturers to switch between different products without significant downtime. It’s particularly useful for industries where product variation is high, such as food, pharmaceuticals, or cosmetics. However, it’s important to note that batch processing may not be as efficient as continuous methods for large-scale production.

Repetitive Manufacturing

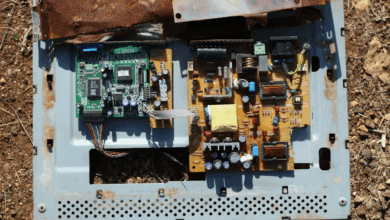

Repetitive manufacturing revolves around the continuous production of the same product over a long period. This process is typically automated and requires little to no change in the setup between production cycles. The automotive and electronics industries often utilize repetitive manufacturing due to its high efficiency and consistency in quality. However, this method lacks flexibility and may not be suitable for products that require customization or are produced in small quantities.

Discrete Manufacturing

Discrete manufacturing involves the production of distinct items that can be easily counted, touched, and seen. Examples include toys, furniture, cars, and appliances. Unlike process manufacturing, where products are the result of chemical reactions or physical transformations, discrete manufacturing assembles individual components into finished products. This process is highly customizable, making it possible to produce a wide variety of products. However, it can be more complex and time-consuming than other methods due to the need for assembly.