The Pros and Cons of Investing in a Laser Marking Machine

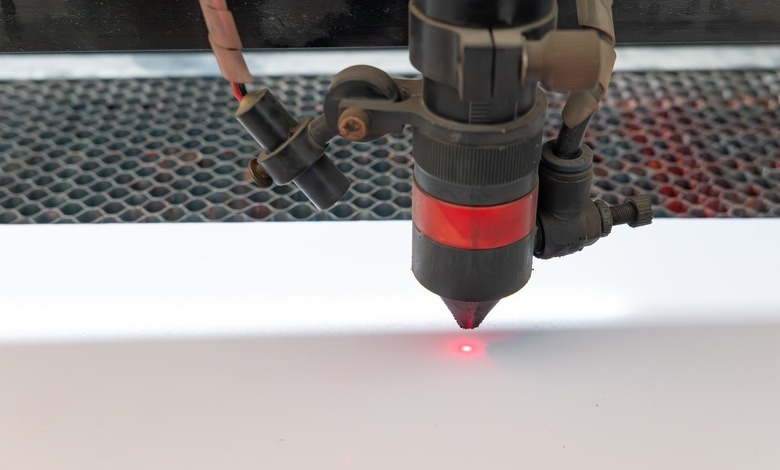

Many industries now utilize laser marking technology due to its permanent, highly durable, and precise marks. From medical devices to automotive parts, this technology is helping businesses achieve unparalleled precision and efficiency.

But laser marking is also an expensive option, so is it worth the cost? In this guide, we’ll break down the pros and cons of investing in a laser marking machine so you can make an informed decision.

Advantages of Laser Marking Machines

There are many benefits of utilizing laser marking for your business. They are versatile, efficient, and cost-effective.

Versatility Across Materials

Laser marking machines excel in their ability to mark a wide array of materials with detail. There are many materials you can mark with laser marking machines, which is what makes them so useful in a wide range of industries. This versatility opens doors for companies in industries ranging from aerospace to consumer goods to streamline their marking needs.

Precision and Quality

One of the standout benefits of laser marking is precision. The technology delivers sharp, clean, and highly durable marks that maintain clarity over extended periods. This level of accuracy ensures that even the tiniest markings, such as QR codes or intricate designs, remain legible and intact.

Speed and Efficiency

Against other, older methods like stamping or engraving, laser marking increases production speed significantly without compromising quality. The automation and advanced technology built into these machines allow manufacturers to mark multiple products in less time, increasing output and reducing downtime. This level of efficiency is particularly appealing to industries with high-volume demands.

Cost-Effectiveness Over Time

Although the initial cost of purchasing a laser marking machine can be high, the long-term financial benefits are compelling. Unlike methods that require consumables such as inks, chemicals, or special tools, laser marking is a clean, maintenance-friendly process. The lack of consumable costs, coupled with durability, makes it an economical choice in the long run.

The Challenges of Laser Marking Machines

We’ve discussed the pros of investing in a laser marking machine, but what about the cons? Laser marking machines have a high price point and require maintenance and servicing to ensure their functionality.

High Initial Investment

The most significant roadblock for businesses is the upfront cost. Laser marking systems, especially high-quality ones for industrial use, represent a considerable financial commitment. For small enterprises or startups, this cost may be difficult to justify, particularly if they don’t utilize the machine to its full capacity.

Maintenance and Servicing

While laser marking machines are relatively low-maintenance, they do require occasional servicing to remain in optimal operating condition. Components such as the laser source and optics need periodic checks, and replacing parts for repairs can be costly. Managers must weigh these costs against the savings gained through operational efficiency.

Is a Laser Marking Machine Right for Your Business?

Investing in a laser marking machine has undeniable benefits, from material flexibility to precision and long-term savings. However, the decision ultimately depends on your business’s needs. High-volume industries or those requiring extreme accuracy will find the advantages outweigh the costs.

For smaller businesses, careful consideration of the upfront investment and potential ROI is essential. By evaluating your operational requirements, budget, and long-term goals, you can determine whether a laser marking machine aligns with your objectives.