Enhancing the Performance of Your Industrial Machines

Industrial machines are essential equipment for many businesses, playing an important role in manufacturing, logistics, and various other sectors. These machines perform complex tasks efficiently and consistently, driving productivity and ensuring smooth operations.

However, their reliability and efficiency depend heavily on proper maintenance to prevent frequent breakdowns, reduced output quality, and expensive repairs. With advancements in technology and evolving industry standards, organizations must adopt effective maintenance strategies and utilize modern tools to enhance the performance of industrial machines. This can lead to significant cost savings and long-term benefits.

Understand the Basics of Each Machine

Optimizing industrial machinery requires an understanding of the fundamental principles behind its performance. Every machine has design specifications that define its operating limits, such as speed, capacity, and functionality. Exceeding or misusing these parameters can lead to inefficiencies and breakdowns.

Operators should be familiar with these specifications to avoid pushing equipment beyond its designed capabilities. Regular training and proper documentation can enable teams to work in harmony with equipment requirements.

Leverage Technology and Automation

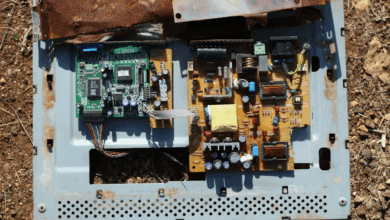

Modern industrial environments benefit from technology integration. Using sensors, monitoring systems, and specialized software can help detect inefficiencies or problem areas in machines. This approach allows teams to make data-driven decisions when addressing equipment concerns. Tools such as IoT-enabled devices provide real-time feedback that helps operators stay proactive when managing equipment health.

Prioritize Preventive Maintenance Schedules

It is essential to adopt preventive maintenance schedules for automation equipment. These schedules ensure that the machinery operates continuously, with minimal downtime required for repairs. By following regular maintenance routines that include lubrication, calibration, and inspection checks, businesses can prevent unexpected breakdowns and ensure processes run smoothly. This approach protects against interruptions, improves operational efficiency, and supports long-term profitability.

Regularly Evaluate and Upgrade Machinery

Even with the best care, certain machines may become outdated or inefficient over time due to technological advancements. Operators should regularly evaluate their equipment to identify signs of declining performance, such as increased energy usage, frequent breakdowns, or production inconsistencies.

Investing in upgrades or modern replacements can generate significant returns by improving output quality and reducing operational expenses. Consider consulting with equipment manufacturers or industry experts to decide whether upgrades or replacements are more appropriate for specific situations.

Enhancing the performance of your industrial machines involves understanding their functionality, committing to regular maintenance, and leveraging technological advancements. With a well-structured plan in place, your industrial operations can continue to thrive in a highly competitive landscape.